When Alon first told me he and his dad David would be flying out to Japan for a Casio factory visit courtesy of Casio Europe, I could tell he was VERY excited. Having joined him on numerous occasions to similar trips to Switzerland, I know for a fact he very much enjoys to meet the people behind the brands, to see their factories, and to hear their stories. And now Casio? To say he was looking forward to his first visit to Japan would be an understatement.

Yesterday Alon sent me the first two batches of pictures he took, along with a summary of his impressions. In the post below you’ll find my transcription of these files.

Casio Factory Trip

A couple of weeks ago we [Ace Jewelers & Watchbase] were invited by Casio Europe to join a small group of retailers for a factory visit in Japan. The group consisted of a total of 8 people: 1 Swedish Casio Authorized Dealer, 1 Austrian Casio AD, 4 German retailers, and us. The invitation both surprised and humbled us, as with Ace Jewelers we just stopped with Casio as we decided to close the boutique that carried it.

So here we are, a few weeks later. Last Monday me and my dad flew out to Tokyo and joined to other members of our group, who all flew in from their home countries. Jet-lagged and all, we were all rather happy our welcome in Tokyo was very relaxed. For dinner we joined the head of Casio Europe at a nice Tempura restaurant.

Day 2 our group was joined by Fujimoto-San (Mr. Hiroshi Fujimoto, Manager Europe & North America Section, Timepiece Department, Overseas Marketing & Sales Division), Takeuchi-San (Mr. Yasushi Takeuchi, Assistant Manager Europe & North America Section, Timepies Department, Overseas Marketing & Sales Division), plus the Sales Manager Europe (Marc), the Managing Director Benelux (Suzuki-San) and Sales Manager the Netherlands, Erik Velthoven. We set off to Yamagata, which is a three hour trip by train from Tokyo.

The mountainous Yamagata prefecture is primarily known for its fruit, among which the best cherries of Japan, apples and pears – and skiing. However, what struck me were the similarities to Switzerland, where in days gone by farmers used to be cut-off from the rest of the world with plenty of time to hone their skills in precision manufacturing. As such, it was hardly surprising that this area -according to our hosts- is often seen as a mini-Silicon Valley in Japanese style, especially when the good infrastructure and kind weather conditions are taken into account. Upon arrival in Yamagata we were treated to a traditional Japanese-style lunch, after which we were invited to the factory.

The official name of the factory we visited is the Yamagata Casio Corporation, Inc., which was founded in 1979 to warrant the highest of quality possible and to secure the ‘Made in Japan’ label . At this location five groups of items are made:

- Premium watches, including movements, cases and bracelets;

- Beamers;

- Camera’s;

- Marine measuring equipment for third parties, and;

- Third party plastic parts (moulding & injection).

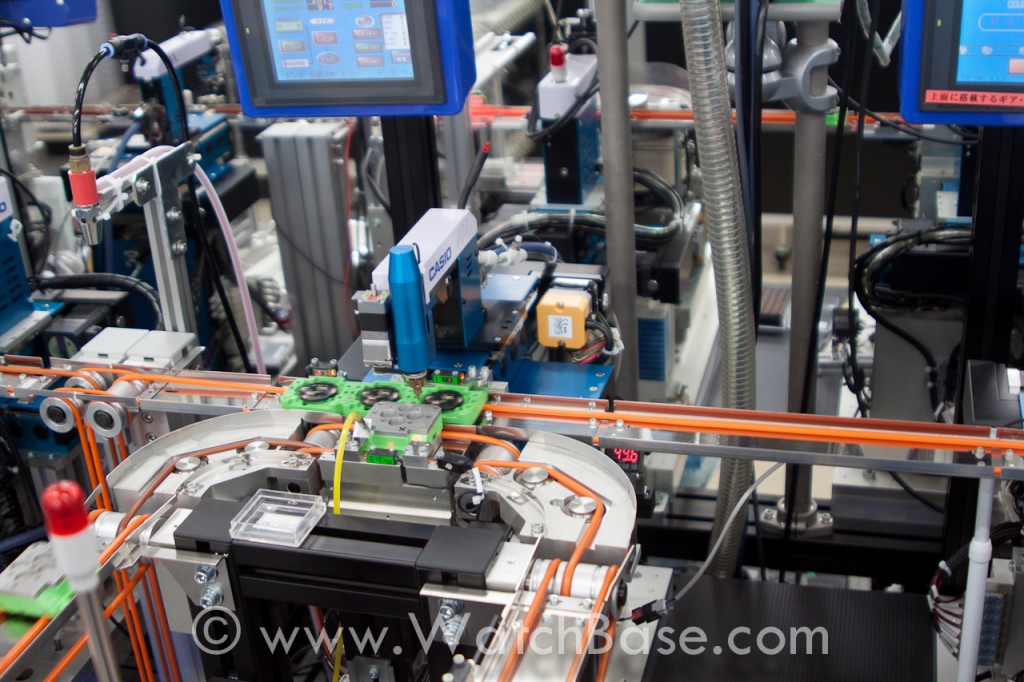

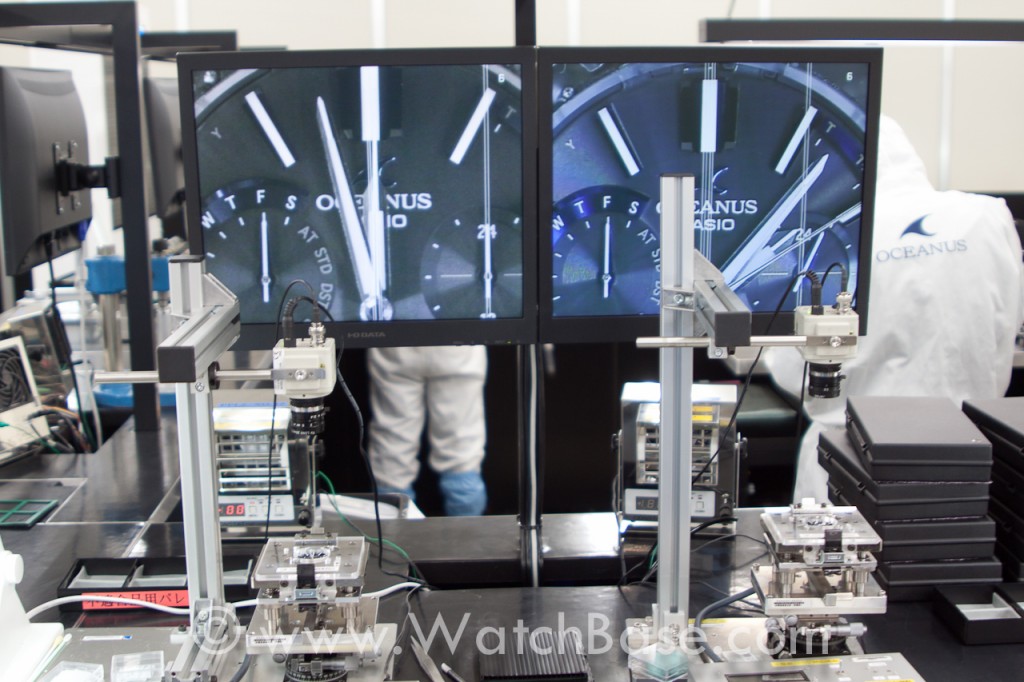

Something I found particularly interesting and impressive was the fact that Casio made all machines, robots and tooling in the factory themselves. All parts are created fully in-house, both with case as well as movement production.

Being a fan of all types of watches you can imagine, I of course had to ask: how about mechanical movements? Well, they never made one nor do they intend to do so: their focus will remain on precision timekeeping and long-term durability. Some 7 years ago Casio decided to further up the quality its watches, and as such high-end collections like the Mr. G, MT-G, Mudman, Oceanus and watches with GPS synching are now produced in Yamagata – with a considerable and unsuspected amount of hand-work that is!

The Yamagata factory currently employs about 700 people, all of which are trained by Casio, at five different levels:

- C: beginner

- B: few months of training and education

- A: Gold – three years of experience

- S: Platinum – an additional 3 years of experience

- SS: Meister – an additional year of experience.

There are not yet any Meisters though, as this programme is not ‘live’ long enough to have any of the employees complete the 7-year training. A number of the people trained at Yamagata will eventually move to Thailand and China and guard and improve the quality of Casio production at the local factories.

Last but not least – in about 7 weeks Casio will make some kind of announcement regarding an intelligent watch.. Having seen the manufacturing power and expertise of this Japanese giant first hand, I can’t wait to see what it is!

Stay tuned!

Full Gallery 2015 Casio Factory Visit Yamagata Part 1